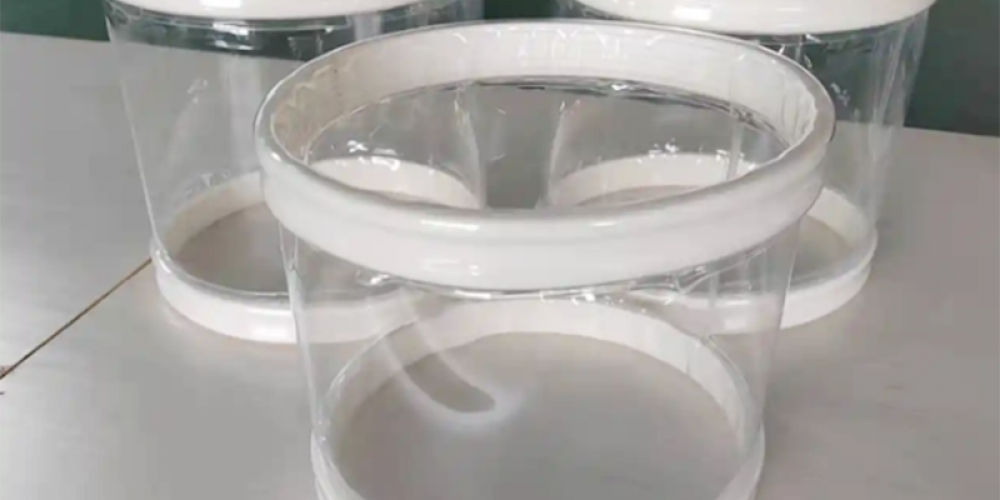

1. High Transparency & Real-Time Monitoring Capability

The TPU soft connector employs food-grade transparent formulations, allowing clear visualization of internal medium flow states. This eliminates operational blind spots caused by traditional opaque materials. For instance, in food processing, operators can directly monitor the transportation of powders or granules, promptly identify blockages or uneven mixing, and reduce downtime for troubleshooting.

2. Outstanding Wear & Tear Resistance

The alternating arrangement of hard and soft segments in TPU’s molecular structure forms a unique "microphase-separated" architecture, combining rubber-like elasticity with plastic-like strength. This enables TPU soft connectors to resist wear in high-frequency vibration or particle-scouring environments, significantly outperforming conventional rubber connectors in lifespan. They are particularly suitable for heavy industries like mining and metallurgy.

3. Oil & Chemical Corrosion Resistance

As a polar polymer, TPU inherently resists mineral oils, hydraulic oils, and weak acids/alkalis, while tolerating certain organic solvents. In chemical production, TPU connectors can transport lubricants or cleaning agents without additional anti-corrosion treatments, reducing maintenance costs.

4. Wide Temperature Adaptability

With a low glass transition temperature, TPU retains flexibility in extreme cold while excelling in high-temperature resistance, enduring short-term exposure to steam or hot oil. This makes it ideal for aerospace and new energy vehicle applications, such as aircraft fuel lines or battery cooling systems, where stable performance is required under drastic temperature fluctuations.

5. Food-Grade Safety & Environmental Compliance

TPU is non-toxic, odorless, and complies with FDA/EU food-contact standards. Its recyclability aligns with green manufacturing trends. In dairy or beverage industries, TPU connectors directly contact food materials without chemical migration risks, ensuring product safety.

6. Dynamic Fatigue Resistance

TPU’s elastic modulus adapts to frequency changes, enabling rapid shape recovery during high-frequency vibrations or repetitive motions to prevent fatigue fractures. For example, in automotive engine compartments, TPU connectors withstand vibrational stress while maintaining sealing integrity, extending equipment service life.