The principle of high-frequency welding for TPU soft joints is based on the skin effect and proximity effect of high-frequency current. It utilizes electromagnetic fields to rapidly heat localized areas of the material to a molten state, followed by mechanical pressure to achieve molecular-level bonding and form high-strength sealed welds. Below are the detailed principles and implementation methods:

I. Core Physical Effects

1. Skin Effect

When high-frequency current (typically 27.12 MHz or 300–450 kHz) flows through a conductor, the current concentrates on the conductor’s surface, exhibiting "surface-concentrated behavior." This property ensures that heat during TPU welding is localized at the material’s surface layer, preventing overall overheating (which degrades performance) while improving heating efficiency.

2. Proximity Effect

When high-frequency currents flow in opposite directions through adjacent conductors, the current aggregates toward the adjacent sides. In TPU welding, by designing the relative positions of electrodes and workpieces, the current path is precisely controlled to focus heat on the targeted welding zone, enabling localized and accurate heating.

II. Welding Process Implementation

1. Alternating Electric Field Generation

A high-frequency power supply generates an alternating electric field between electrodes. The TPU (as a dielectric material) is sandwiched between the electrodes. The electric field induces intense molecular friction within the TPU, generating heat. Due to rapid heat dissipation at the electrode-material interface, heat concentrates at the internal junction of the TPU, forming a molten layer.

2. Molten Phase and Compression Bonding

- Molten Phase: Continuous high-frequency current melts the targeted TPU area into a plasticized state.

- Compression Phase: Mechanical pressure (e.g., rollers or molds) compresses the molten zone, expelling oxide layers and impurities while enabling molecular chain interpenetration to achieve atomic-level bonding.

- Cooling Solidification: After deactivating the high-frequency power, the molten zone rapidly cools, resulting in weld strength comparable to the base material and a smooth, protrusion-free surface.

III. Technical Advantages & Features

1. High Efficiency & Precision

- Ultra-fast heating (millisecond-level welding) suitable for automated production.

- Heat localization minimizes thermal distortion risks by avoiding excessive heat-affected zones (HAZ).

2. Superior Seal Integrity

- Molecular-level bonding ensures high strength, pressure resistance, and corrosion resistance, meeting hygienic requirements for food/medical industries.

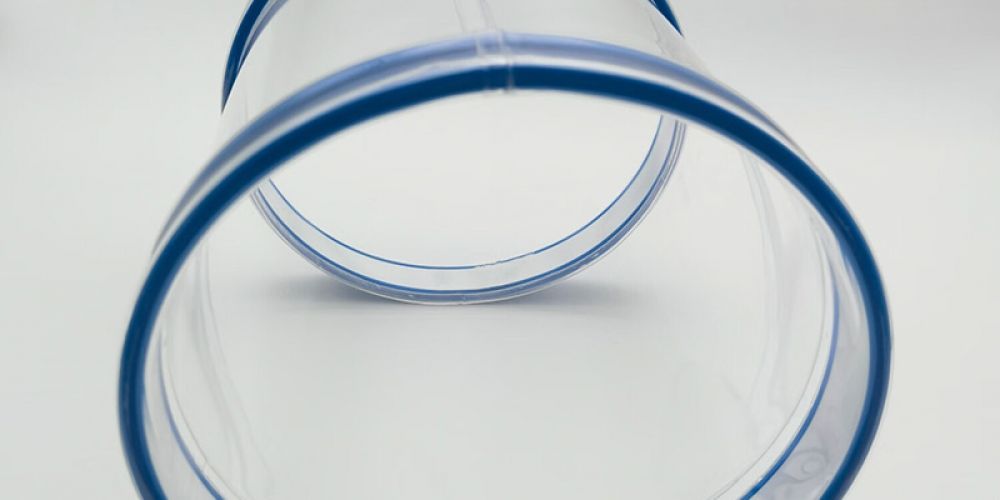

- Transparent TPU retains high light transmittance post-welding, enabling real-time monitoring of internal fluid flow.

3. Material Adaptability

- Welds TPU materials of varying thicknesses (0.1–5 mm) and hardness levels, including functional grades (anti-static, conductive).

- Adjustable frequency and pressure enable hybrid welding of flexible soft joints with rigid structures.

4. Eco-Friendly & Safe

- Solvent/glue-free process with zero VOC emissions, compliant with RoHS and REACH regulations.

- No sparks or splatter during welding ensures operational safety.