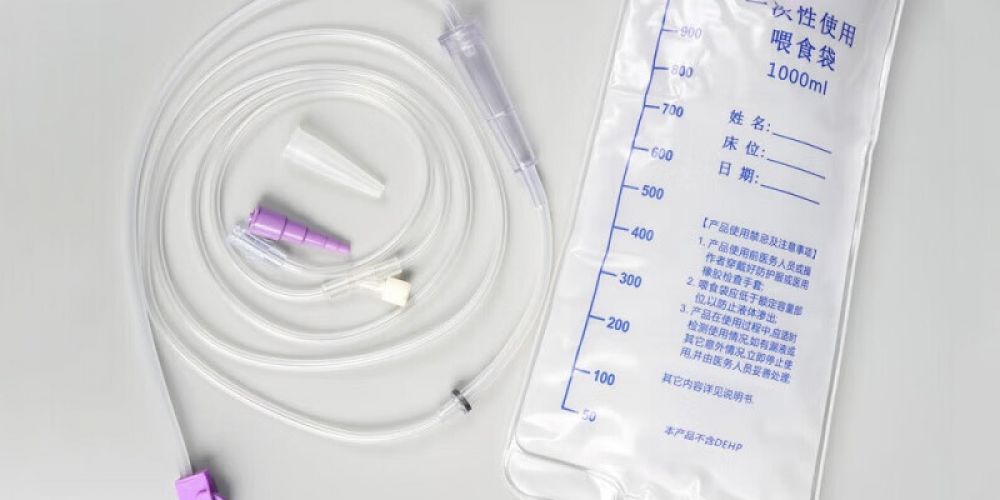

High-Frequency Welding Technology in Medical Drainage Bag Manufacturing

High-frequency (HF) welding enables molecular-level fusion of medical-grade plastics through dielectric heating (27.12/40.68 MHz), revolutionizing drainage bag production. Key innovations:

Technical Leap

Clinical Impact

Versatile Processing

3D Integration

Line Integration

Safety Systems

Biosafety

Eco-Production