Driven by global plastic restrictions and carbon neutrality goals, the packaging industry is undergoing a transformation from traditional plastics to bio-based and biodegradable materials. With its low-temperature sealing and pollution-free emission characteristics, constant-temperature heat sealing machines have become core equipment for eco-friendly packaging manufacturing, revolutionizing sectors such as medical device packaging.

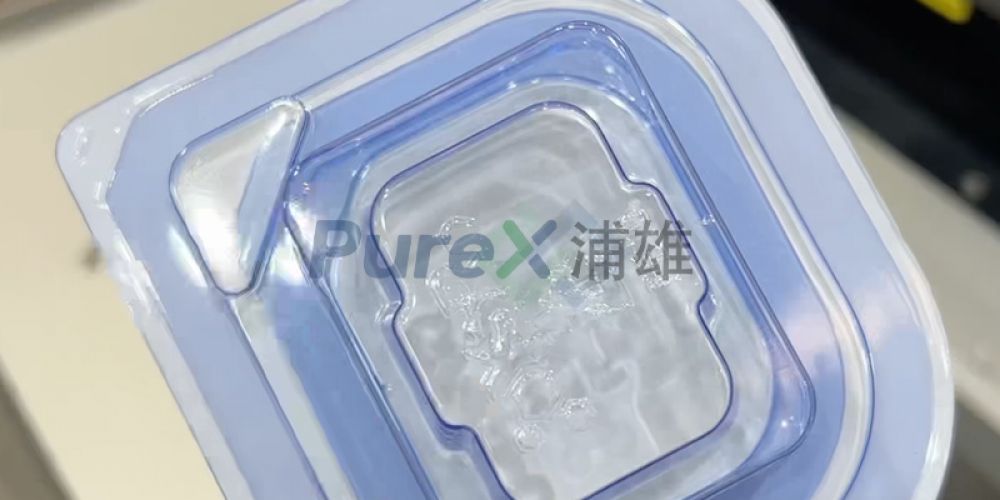

Medical device packaging demands exceptional sealability and clear identification. Constant-temperature heat sealing machines enable hermetic sealing between blister cavities and medical-grade paper (e.g., Tyvek) or aluminum foil. One medical device manufacturer adopted this process, achieving a sealing strength of 20N/15mm and zero damage rates in drop tests. An even more innovative application is permanent marking technology—using customized molds to emboss QR codes onto packaging surfaces. These codes maintained a 100% recognition rate after 100 friction tests, effectively resolving traceability failures caused by traditional printing methods.

In the medical industry, packaging is not merely an "outer layer" but a critical component ensuring sterility, safety, and full traceability. Through innovative processes and material applications, Puxiong has successfully established a dual technical system of "sealing protection + intelligent traceability," setting a new benchmark for medical device packaging.

The sealability of medical device packaging directly impacts product sterility. By employing constant-temperature heat sealing technology, the manufacturer achieves molecular-level welding between blister cavities and medical-grade paper/aluminum foil through precise temperature and pressure control. This process overcomes the limitations of traditional heat sealing:

Traditional printed labels are prone to wear, moisture, or chemical corrosion, leading to broken traceability chains. The manufacturer innovatively applies mold-embossing technology to directly imprint QR codes onto packaging surfaces, achieving "one-step formation, lifelong readability":